01HIGHLIGHT

FY2019

CSR Activity

Highlights

Significantly Increasing

Recycling Efficiency

with PET Bottle Labels that Float on Water

Supporting Plastic Recycling in Europe with

TOPAS®COC

Plastic is a highly convenient material indispensable to contemporary society, but the large role it plays in marine littering and global warming has become the subject of some concern in recent years.

As a means of addressing these problems, there has been a rapid shift, both in regulatory requirements and public opinion, away from disposable plastics and towards recyclable plastics as a way of fostering the establishment of a more recycling-oriented society, and this has created a heightened need for plastics capable of being efficiently recycled. In the case of PET drink bottles, the key difficulty has been the bottle label material, but now Polyplastics’ TOPAS®COC is being utilized to create an easily recyclable label material.

Searching for an optimal method of removing labels from PET bottles

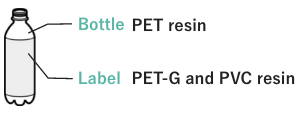

PET drink bottles are made up of a bottle, a cap and a label, each of which is manufactured from different resins. In order to efficiently recycle a PET drink bottle, it is necessary to separate these resins from one another. If these different materials are all recycled together, then the purity of the recycled plastic is degraded, which limits its potential applications.

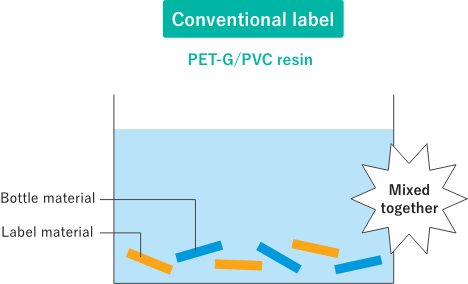

Countries in Europe have investigated a variety of ideas for removing labels from bottles, including equipping recycling plants with specialized label removal machines and calling on consumers to remove labels from bottles; however, from a cost vs. benefit standpoint, none of these approaches can be described as effective. An idea which is currently attracting attention is to utilize a difference in specific gravity between the materials so that only the labels float in water, causing them to separate from the PET flakes which make up the bottle itself. This would allow highly pure resin to be recovered.

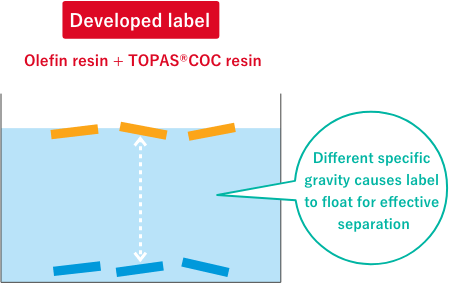

To do this, a label material is needed which performs all of the essential functions of a label but which also will float in water.

Using TOPAS to provide a buoyant, easily recyclable material that can function as a label

PET bottle labels need to be able to retain ink printing as well as be able to shrink and adhere to the PET bottle. Traditionally, PET-G and PVC resins are commonly used to make labels, but because the specific weights of these materials are too large to float in water, the aforementioned method cannot be used to remove them from the bottle. Now, Polyplastics has developed a buoyant, low specific gravity label using TOPAS®COC resin. TOPAS makes it possible to create a material which is buoyant while also providing the optimal characteristics needed for a label. This helps to improve the recycling rate of PET bottles by efficient separation. Additionally, despite the fact that TOPAS is a different material to PE and PP olefin resins, it has the same framework structure as olefin resin; thus, in general, it is possible to recycle this label along with other olefin resins.

Helping Europe Address the Challenge of Recycling PET Drink Bottles

In order to create highly pure, recycled plastic,

the bottle and label need to be recycled separately;

however, there is no clearly cost-effective method for removing labels from bottles.

Achieving Efficient Removal with Labels Made from TOPAS®COC Resin

By developing a label material which retains the functionality required for a label but which is also buoyant in water, labels can be removed from PET bottles by putting them in water so that the label material remains afloat while the bottle material sinks.

- Fulfills the functions of a label, but is unable to float.

- Both bottle and label end up mixed together at the bottom of the water bath.

- PE and PP olefin resin floats because it has a lower specific gravity than water.

- The properties of TOPAS allow it to maintain the functionality required for labels.

Strengthening the supply system and contributing to a more recycling-oriented society through a combination of engineering plastic and technology

With the demand for TOPAS rapidly increasing, the number one issue is how to bolster the supply system. In order to make sure that we are able to provide a stable supply of high-quality product, we are planning to increase the production capacity of our existing equipment by 50% at the start of FY2021 and to bring new equipment on-line during FY2022.

At the same time, we will be working to raise market awareness of TOPAS as a recyclable olefin material. Global warming and marine littering are problems which affect the entire world, not just Europe. We will continue to use a combination of engineering plastic and technology to help find solutions that will enable society to recycle, and thereby maximize the usable life of, plastics made from our earth’s limited petroleum resources.