Our Approach

2022

PLASTRON® LFT long cellulose fiber reinforced thermoplastic resin

Weight reduction plus mechanical strength in an eco-friendly biomaterial

Sustainability has also been sought in product development in recent years, and eco-friendly resins that incorporate natural fibers, starch, wood powder, and other plant-based and natural mineral filling materials are being considered for use in a broader range of scenarios. However, in many cases these eco-friendly resins lack mechanical strength, which is a point of concern.

Polyplastics long cellulose fiber reinforced thermoplastic resin (PLASTRON® LFT) is a product designed to satisfy the needs of those who want to use biomaterials but are unwilling to compromise on mechanical strength.

Features

(1) Eco-friendly, made from cellulose which is a biomaterial

(2) Can make products more lightweight

(3) Has high mechanical strength (particularly impact strength)

Made from regenerated cellulose*1 for both sustainability and balanced physical properties

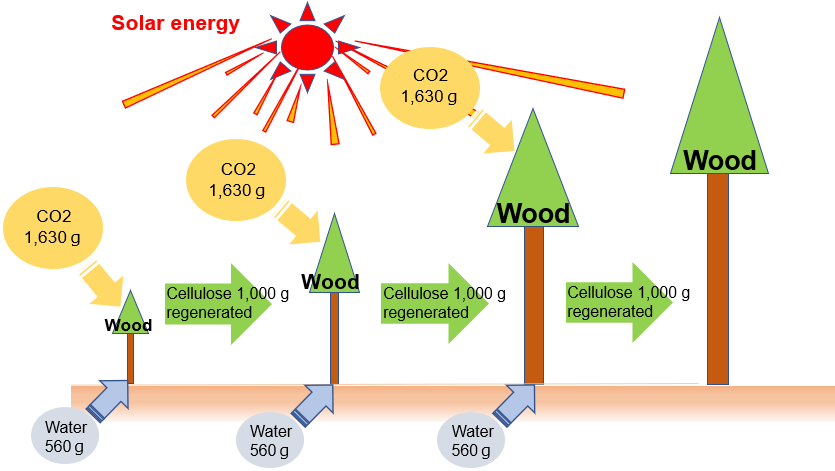

Cellulose is a material present in plants such as trees and grass. It is the most commonly occurring type of organic matter on earth and holds the potential to help reduce CO2 emissions.

When used as a reinforcing material for resin, natural cellulose fibers have insufficient strength because they are short fibers. Polyplastics has addressed this problem by using regenerated cellulose fiber*1 to develop long cellulose fiber reinforced thermoplastic resin with an excellent balance of physical properties. We have acquired multiple patents for this technology in Japan and internationally.

*1 Regenerated cellulose fiber: Natural cellulose spun into continuous fibers through wet spinning.

Low density offers potential for weight reduction of products

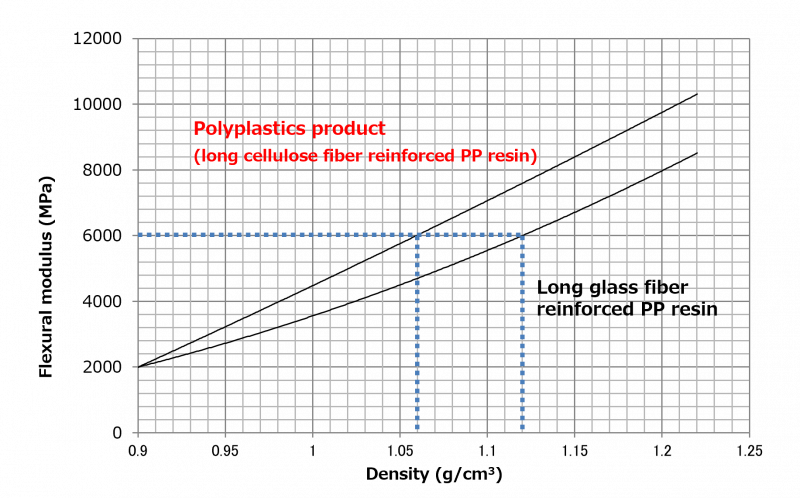

When comparing long cellulose fiber reinforced PP resin against long glass fiber reinforced PP resin at the same flexural modulus, we see that cellulose-reinforced resin has lower density than glass-reinforced resin. (Figure 1)

Figure 1 : Comparison of long cellulose fiber reinforced PP resin against

long glass fiber reinforced PP resin (density vs. flexural modulus)

Biomaterial PLASTRON® LFT offers potential for higher strength

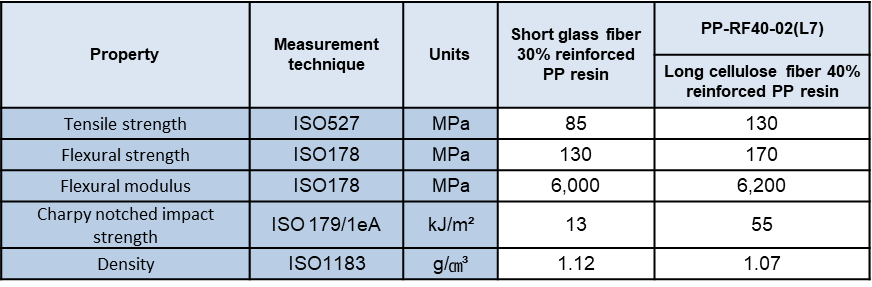

Table 1 compares the physical properties of Polyplastics PLASTRON® LFT long cellulose fiber 40% reinforced PP resin (PP-RF40-02) and short glass fiber 30% reinforced PP resin with roughly the same flexural modulus. Although they have almost the same flexural modulus roughly, it shows higher values for Charpy impact strength, tensile strength, and flexural strength, indicating potential for upgraded strength.

Table 1 : Comparison of Long cellulose fiber reinforced PP resin and Short glass fiber reinforced PP resin

Product development initiatives to reduce waste in addition to CO2

Since cellulose is highly insoluble in solvents, a large portion of regenerated cellulose fibers are manufactured through long and cumbersome processes. Simplifying these processes would likely lead to a further reduction in CO2.

Polyplastics is currently developing regenerated long cellulose fiber resins using what we call the solvent method, a simple manufacturing process that emits very little CO2. Since this method involves a closed process that recovers virtually 100% of the solvent, it generates hardly any waste and produces materials that are even more eco-friendly.

Polyplastics will continue striving to help create a sustainable society.

For details, please contact a Polyplastics sales representative or inquire through “Contact Us” at the top-right of the screen.

【Related information】

◆ Long Cellulose Fiber Reinforced Thermoplastics: PLASTRON® LFT

【Technical data sheet is available online】

◆ PP-RF-40-02(L7)

【For inquiries about our technologies and materials, please contact us via】

◆ Polyplastics Group Representative

◆ WEB Inquiry