Our Approach

2022

Predicting vacuum voids using POM is now possible with high accuracy: We can support your design development with our original analysis technology

Polyplastics has developed a technology that uses CAE analysis to predict the occurrence of voids*1 in DURACON® POM injection-molded products. Since this technology can predict the risk of voids forming before creating the mold, it could help reduce numbers of trial samples, shorten the development cycle, and cut down on energy usage.

*1: One type of molding defect, in which hollow pockets form in the thicker parts of molded products

Voids are one type of molding defect

There is a phenomenon in which hollow pockets form near the center of thick parts of injection-molded products, and these hollow pockets are called voids. Parameters such as volume shrinkage that is produced as output from flow analyses had conventionally been used for void prediction, but the accuracy of this method has been problematic since the actual phenomenon cannot be recreated and for other such reasons.

As for analyzing the causes of defects in prototypes and products on the market, voids are now easy to discover due to the spread of non-destructive technologies for visualizing the interiors of solid objects such as X-ray computed tomography. Technologies related to controlling voids are now expected to dramatically improve.

Ability to predict voids with higher accuracy than conventional methods

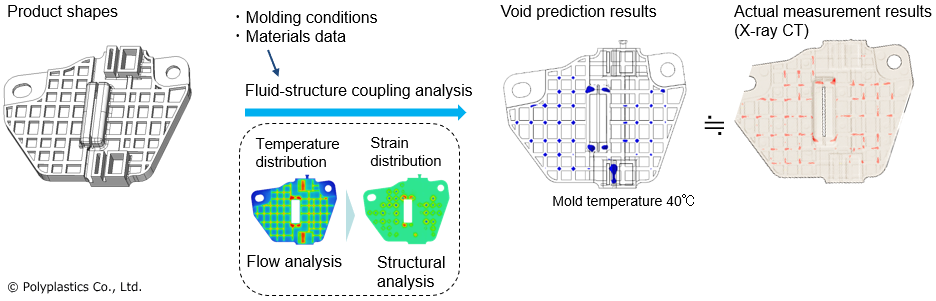

The new technology we have now developed is an entirely new method that links flow analysis with structural analysis to predict the formation of voids according to strain arising inside molded products, taking into consideration mold shrinkage, elastic modulus, and distribution of pressure in the resin solidification process. Since it can predict voids with high accuracy before work to create the mold begins, this technology promises to reduce the development cycle, cut down on product development costs, and reduce the consumption of energy needed for simulations.

The analysis results in the figures below are examples obtained using this technology. The blue areas shown in the void prediction results generally match the red areas from actual test results, thus verifying that the predictions are sufficiently accurate. We have also been testing this technology’s capabilities in various other shapes.

<Developed technology (linking flow & structural analysis)>

As part of our technical services – now answering inquiries regarding void prediction technology

Utilizing this technology, we support our customers’ product development starting from the design phase. We are also advancing technological development for new solutions, including sink mark*2 prediction technology that leverages this void prediction technology.

If you have any questions about predicting voids in the shapes of molded articles or wish to reach us to discuss experimental considerations about the formation of voids or any other questions or requests, please either contact one of our sales representatives or click “Contact Us” at the top-right of this page to inquire.

*2: Depression deformations occurring on the surfaces of molded products

[ For inquiries about our technologies and materials, please contact us via ]

◆ Polyplastics Group Representative

◆ WEB Inquiry