Our Approach

2023

Polyplastics to launch a new re-compounding service under the DURACIRCLE® sustainability initiative

The DURACIRCLE® initiative aims to recycle 100% of engineering plastics

As an industry leader in engineering plastics, Polyplastics is implementing its DURACIRCLE® initiative for the recycling of engineering plastics. This project will apply a wide variety of sustainable solutions that contribute toward achieving a 100% recycling rate, without being confined to the existing business model of simply manufacturing and selling materials.

Phase one of DURACIRCLE® : Re-compounding Service

Utilizing our long history of engineering plastics material development and manufacturing technologies Polyplastics has launched the “Re-compounding Service” in 2023. This service offers our customers the highest quality in mechanically recycled*1 materials.

*1 Mechanical recycling is a method to melt plastic waste with heat and process it back into pellets for reuse, also referred to in Japan as material recycling.

Features of Re-compounding Service

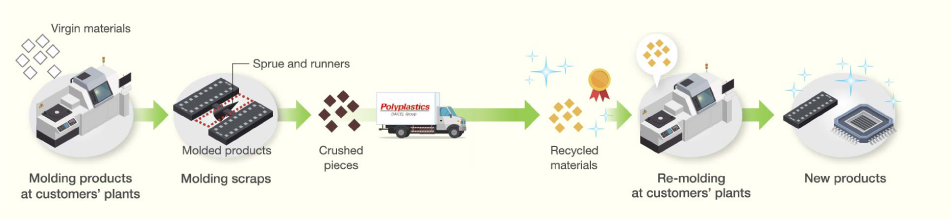

【Illustration of our Re-compounding Service】

Re-compounding Service is a clear departure from conventional recycling. It was named “Re-compounding” with the aim of application in horizontal recycling*2 which is considered difficult with engineering plastics since they need to be of the highest quality. In the immediate future, we anticipate using pre-consumer materials*3 as raw feedstocks as they have traceable manufacturing histories and therefore pose little risk of contamination from environmentally hazardous substances.

*2 Horizontal recycling is a recycling method to recycle products into the same products, such as recovering plastic bottles and recycling them back into plastic bottles.

*3 Pre-consumer materials are raw materials to be recycled such as runners and non-conforming products that arise in manufacturing processes before products reach consumers, also referred to as post-industrial recycling (PIR).

Polyplastics plans to develop and offer recycling technologies for post-consumer recycled materials (PCR) which are even harder to reprocess. As environmental needs evolve, Polyplastics is developing future solutions for mechanical recycling, chemical recycling, and biogenic carbon cycles.

(Updated on 8th Oct 2024)

【Related information】

◆Special Web Page for Sustainable Solutions under the “DURACIRCLE®” Initiative

[ For inquiries about our technologies and materials, please contact us via ]

◆ Polyplastics Group Representative

◆ WEB Inquiry