Our Approach

2023

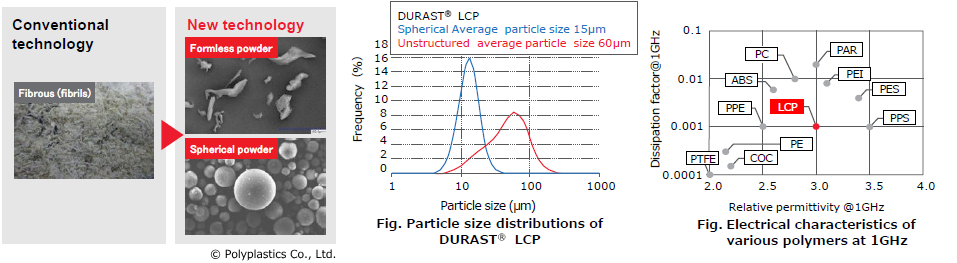

【4/19Document Update】Engineering Plastics Innovation: New DURASTⓇ Powder

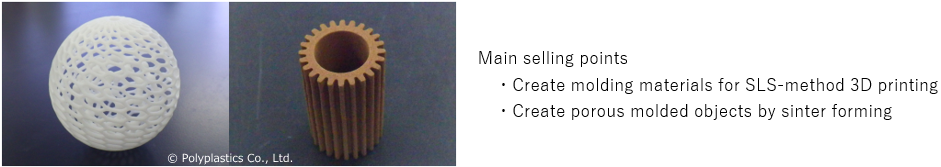

Improves product characteristics and helps reduce material loss

Introduction

At Polyplastics, we mainly offer pellet-shaped engineering plastics for injection and extrusion molding. In expanding our lineup, we considered how we could accommodate demand from customers who have expressed the desire to also use engineering plastics and add new functionalities to products in manufacturing methods for which pellets are incompatible. Believing that powder form could be one solution, we developed DURASTⓇ Powder in a distinctive shape with fine, narrow particle size distribution. We now offer this material that makes new functionalities possible.

| Market Demand | Solution | Achievements / Applications | ||

|

Materials compatible with many different types of manufacturing methods are needed to manufacture products in small quantities with many varieties or with complex shapes. |

Offer powder resin with fine, narrow particle size distribution (10 μm-200 μm) |

Enables improvements to properties and compatibility with various manufacturing methods as follows |

Here are four Polyplastics resins that we currently offer.

| DURASTⓇ POM | DURASTⓇ PPS | DURASTⓇ PBT | DURASTⓇ LCP (under development) |

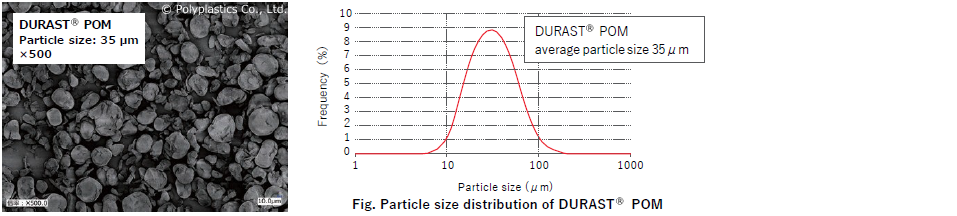

| ■ DURASTⓇ POM |

||||

| Polymer | Form | Average particle size | Heat resistance | Characteristics |

| Polyacetal (POM) |

Formless | 30~100μm | 90~100℃ | Being a copolymer, it has good thermal stability and superior flexibility. It also has self-lubricating properties and superior friction resistance, as well as high rigidity and elastic recovery rate. |

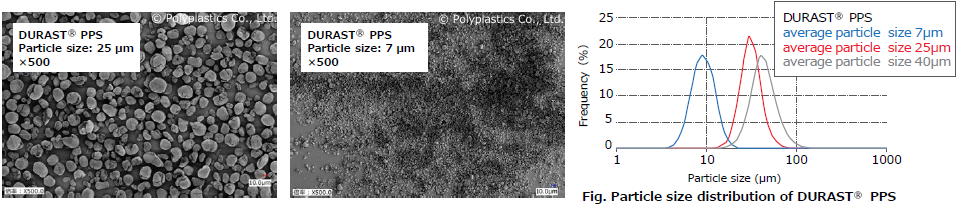

| ■ DURASTⓇ PPS |

||||

| Polymer | Form | Average particle size | Heat resistance | Characteristics |

|

Polyphenylene Sulfide |

Formless | 7~200μm | 100℃ | It is a linear type PPS with high toughness and heat resistance, as well as chemical resistance and resistance to radiation, and since it has few ionic impurities it can also stand up to rigorous requirements for electrical properties. Its superior affinity with metal also enables formation of composites. We offer a lineup of various particle sizes and viscosities according to the usage application. |

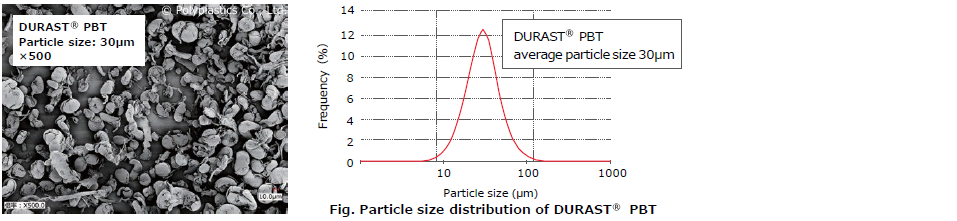

| ■ DURASTⓇ PBT |

||||

| Polymer | Form | Average particle size | Heat resistance | Characteristics |

| Polybutylene Terephthalate (PBT) | Formless | 30~100μm | 65~70℃ | It is tough, with plenty of flexibility and low water absorbency, and superior electrical insulation properties in a broad range of temperatures and humidity levels. Its heat distortion temperature is 65-70°C (depending on degree of crystallinity). |

| ■ DURASTⓇ LCP (under development) |

||||

| Polymer | Form | Average particle size | Heat resistance | Characteristics |

| Liquid Crystal Polymer (LCP) |

Sphere |

[Sphere] 10~50μm [Formless] 50~100μm |

Depends on type of polymer | Offers superior vibrational absorption properties with high heat resistance and high elasticity. It also has superior flowability and gas barrier properties in addition to low water absorption rate and electrical properties that are stable at high frequencies. Through our advanced powderization technologies, we have developed both a formless powder with less fibrils and less orientation compared to previous materials and a spherical powder. |

※Document Update(19.April.2023)

Conclusion

Engineering plastics are materials with high molecular weight and high mechanical strength. For that reason, when they are processed through methods such as pulverization, friction heat between different resins or with the pulverizer machine can cause resins to melt. At Polyplastics, we conducted wide-ranging research on powder manufacturing methods, through which we successfully developed distinctive engineering plastic fine powders. These powders offer potential usage in a wide range of manufacturing methods.

We offer particle samples of each type of resin, so if you are interested please contact us either through a sales representative or via “Contact Us” at the top-right of the screen.

【For inquiries about our technologies and materials, please contact us via】

◆ Polyplastics Group Representative

◆ WEB Inquiry