News

2023

Polyplastics Sees Strong Potential for POM and PP in Thermal Management Systems for EVs

Polyplastics

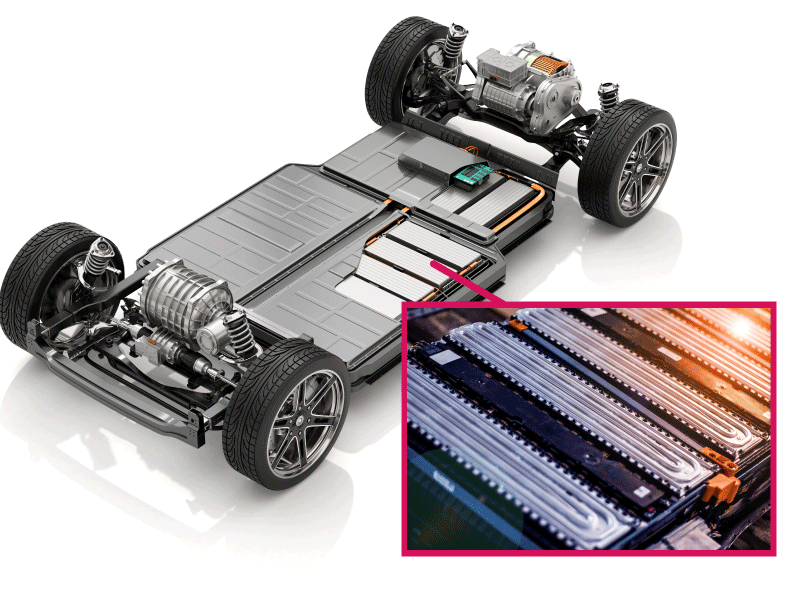

As the automotive industry moves from traditional combustion engine vehicles to battery electric vehicles (BEVs), OEMs and parts manufacturers are reimagining the types of materials that can meet the thermal management needs of EVs. Polyplastics Group, a leading global supplier of engineering thermoplastics, sees strong potential for less heat-resistant plastics like POM and PP for production of EV cooling components.

The coolant in combustion engines is typically maintained at a temperature of 70-100°C but can climb to 120°C or higher if the engine overheats. Therefore, metals or high heat-resistant plastics like polyphenylene sulfide (PPS) are used in cooling components and lines. In comparison, EVs require a long-life coolant (LLC) temperature of 100°C or lower. This allows for the use of less heat-resistant materials for BEV-specific components.

When the temperature of a long-life coolant is 100°C or lower, general-purpose engineering plastics like polyoxymethylene (POM) or polypropylene (PP) can be used instead of metals or high-performance engineering plastics. In the case of PP, Polyplastics sees potential for PP-LGF (long-glass fiber) instead of short glass fibers to increase strength, dimensional accuracy, and overall performance. Polyplastics also offers DURACONⓇ bG-POM made with biomass as an eco-friendly option.

Replacing high heat-resistant plastics such as PPS with POM and PP not only reduces material costs but also helps with efforts to reduce CO2 by reducing the carbon footprint of materials and energy consumption during molding.

When conventional materials are replaced with low thermal resistance materials, durability becomes a concern. Polyplastics conducts extensive immersion testing on LLCs, gathering data on each plastic type. The company offers design assistance using CAE and provides guidance based on the data.

For more information, visit https://www.polyplastics-global.com/en/approach/24.html

SDGs related to this article