News

2025

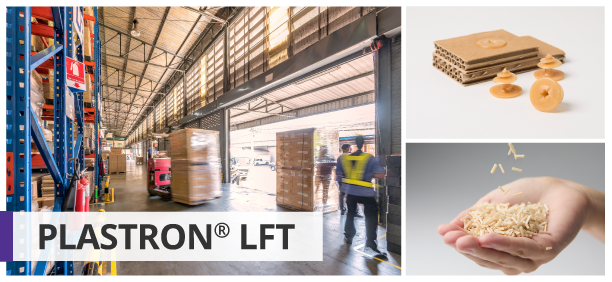

Case study for PLASTRON® LFT: Adopted as a packaging material for a logistics company

Polyplastics

Polyplastics has published an article titled “Adopted as a packaging material for a logistics company: Long cellulose fiber reinforced resin for both CO2 reduction and strength” on its website.

EMUNEJI is a plastic item to fasten cardboard boxes for transportation. Metal fasteners may require specialized tools and skilled labor to install, but EMUNEJI can be easily installed with an electric screwdriver, thus enhancing work efficiency. In addition, since the screw tips do not stick out, this product is designed for safety during and after installation.

Made possible by long cellulose fiber reinforcement: High impact strength and excellent rigidity

When packaging materials for transportation are used for export, they must be strong enough to withstand the harsh logistics environment. However, biomass materials generally have low strength.

Our PLASTRON® LFT uses long cellulose fiber to produce higher impact strength and superior stiffness.

From an environmental standpoint, this cellulose fiber is a sustainable material derived from trees. Unlike glass fiber and metals, no residue is generated during incineration, enabling “thermal recycling” that leads to reduction of industrial waste.

Toward a sustainable future

PLASTRON® LFT, which utilizes wood-derived cellulose, a biomass raw material, is available in three types of grades. For details on the features and physical properties of each type, please refer to the downloadable documents on our webpage:

https://www.polyplastics-global.com/en/approach/36.html

Furthermore, we are developing new grades utilizing PCR (post-consumer recycled) materials with the aim of further reducing environmental impact.

SDGs related to this article

![]()

![]()