Our Approach

2022

Improved Precision / Cycle Time / Damage

Laser Weldable DURAFIDE® PPS

The use of laser welding in manufacturing is becoming more widespread in recent times, particularly for automotive sensors and actuators, due to benefits in the production process in terms of lower CO2 emissions, space efficiency, and time saving.

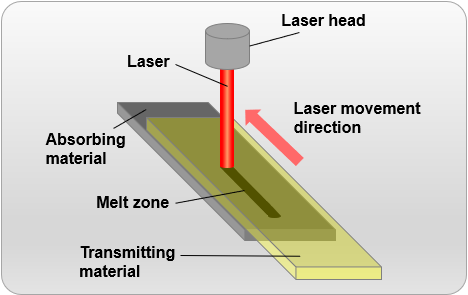

[What is laser welding?]

Laser welding is a technology that uses energy from a laser beam to weld two molded products. It is performed by combining material that transmits lasers with material that absorbs lasers.

Since it offers high bonding strength and air tightness in addition to no physical stress from vibration or ultrasonic sound, laser welding is highly suitable for welding precision parts and components. It also consumes less electricity than processing methods such as adhesion, hot plate welding, and vibration welding.

Figure: Diagram for Laser Welding

Figure: Positioning of various welding techniques based on welding time and energy consumption

[Laser transmitting DURAFIDE® PPS by Polyplastics]

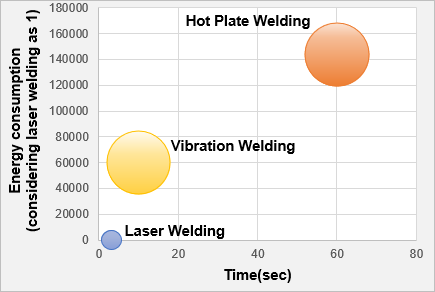

As mentioned above, laser welding is a processing method that offers a long list of advantages, but it has been difficult to actually use on PPS (polyphenylene sulfide) which has low laser transmittance.

Polyplastics linear-type DURAFIDE® PPS is characterized by its white natural color, as opposed to the reddish-brown natural color of other companies’ PPS.

That gives it superior laser transmissibility (light transmissibility in the infrared region) and makes laser welding possible.

Figure: Color shades of linear type and cross-linked type PPS

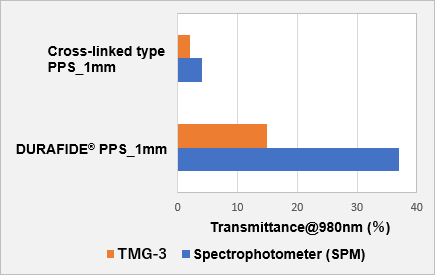

Figure: Comparison of Laser Transmittance of Linear Type and Cross-Linked Type PPS (Glass Fiber Reinforced)

Characteristics of DURAFIDE® PPS

(1) High transmittance: Wide process window (broad range of welding conditions)

(2) High toughness: Advantageous for initial strength and durability

Using DURAFIDE® PPS enables the use of laser welding on automotive electric components for which this method could not readily be used before.

We are currently developing PPS engineered for even better transmittance.

[ For inquiries about our technologies and materials, please contact us via ]

◆ Polyplastics Group Representative

◆ WEB Inquiry