Our Approach

2023

DURAFIDEⓇ PPS maintains part shape and insulation properties during EV battery thermal runaway

The automobile industry is on the cusp of a massive once-in-a-century transformation with the keyword “CASE” at the epicenter. Part of this is ”E” for Electrification, in which OEMs are accelerating the shift from engine-powered vehicles to electric vehicles against the backdrop of global environmental issues. Electric vehicles are equipped with potentially volatile components such as lithium-ion (Li-ion) batteries (LIBs). These batteries can cause abnormal heat generation due to thermal runaway when accidents and other disturbances occur, and ultimately lead to fires. To prevent this, we developed a PPS material that bolsters thermal and electrical insulation properties.

Thermal runaway in lithium-ion batteries (LIBs)

During a thermal runaway event, a LIB cell can reach temperatures of 800 to 1,000°C, and the gas it ejects can reach 700 to 800°C. If thermal runaway occurs in one cell, energy transfer to neighboring cells must be reduced. However, since resin is an organic material, it decomposes and turns into gas in environments 500°C or hotter, making it unable to maintain its thermal and electrical insulation properties. Although necessary for safety measures, these sheets and plates increase weight and consume space due to the increased number of parts. We propose a solution to these problems with our DURAFIDEⓇ PPS 6150T73.

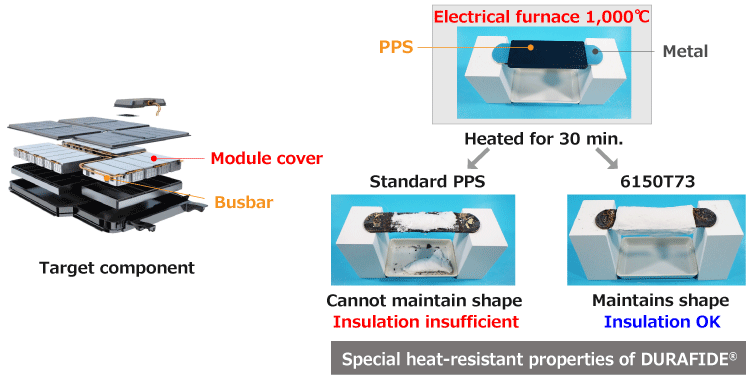

DURAFIDEⓇ PPS 6150T73 capable of maintaining busbar coverage at 1,000°C

As shown in the photo, DURAFIDEⓇ PPS 6150T73 is a material that contributes to insulation during thermal runaway without inorganic sheets, because it can maintain the coating of busbars even after being left in environments of 1,000°C for 30 minutes.

Optimal properties for components inside batteries such as module covers and busbars

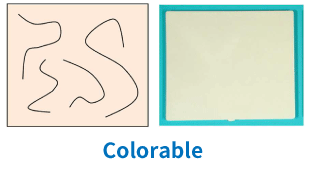

In addition to special heat resistance, DURAFIDEⓇ 6150T73 has properties that make it ideal for module covers and busbars in LIBs. The polymer we use is high-purity linear PPS, which can be colored.

Linear PPS:DURAFIDEⓇ

● High toughness and excellent impact strength

● Low ionic impurities (extracted components)

● Color is close to white and can be tinted

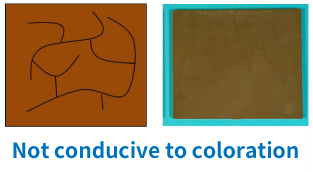

Cross-linked PPS

● Low toughness

● High ionic impurities

● Brown in color and difficult to tint

The downloadable documents also provide detailed information on heat shock resistance test data and physical property tables. If you have any questions or requests, please contact our sales representatives or click “Contact Us” in the upper right corner of the screen.

[ For inquiries about our technologies and materials, please contact us via ]

◆ Polyplastics Group Representative

◆ WEB Inquiry