Our Approach

2025

【Video】Evolution of 3D Printing Technology Using DURACON® POM: Enabling High-Performance, High-Precision Fabrication

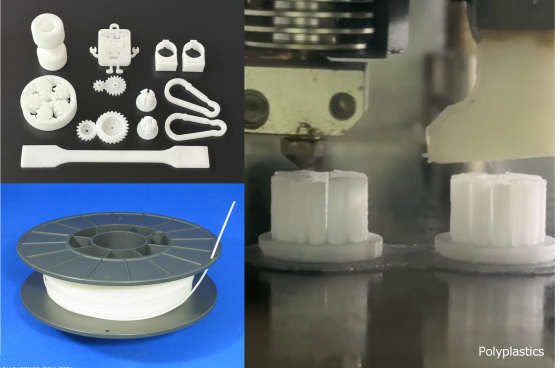

Polyplastics has established and expanded 3D printing technology using the crystalline engineering plastic DURACON® POM (acetal) through a material extrusion (MEX*1) method.

This technology achieves physical properties and precision in shaping that rival injection molded products, contributing to shorter product development cycles.

Currently, its application is being explored across various industries.

*1: Material Extrusion (MEX), a common 3D printing method using thermoplastic resins, is also known as FFF(Fused Filament Fabrication).

Achieving Physical Properties Comparable to Injection Molded Products and Creating New Value

We have established 3D printing technology using material extrusion with crystalline engineering plastic “DURACON® POM” through our special grade “DURACON® POM AM17X,” optimized for 3D printing, and proprietary 3D printing conditions (Patent Pending).

This technology enables 3D printed parts to achieve physical properties comparable to injection molded products. As a result, it allows for prototyping and preliminary evaluations of properties, functionality, and durability without the need for molds, contributing to faster product development cycles.

In addition, it offers new value, such as:

Realization of complex geometries difficult to achieve with conventional manufacturing methods.

Integration of multiple components, leading to reduced part count and weight savings.

Achieving the Excellent Properties of POM in 3D Printed Parts

One of the most common 3D printing methods using thermoplastic resin materials is Material Extrusion (MEX). In the MEX process, thermoplastic resin filaments are heated and extruded through a fine nozzle, then layered to build up precise three-dimensional structures.

Traditionally, resins suitable for MEX 3D printing have been limited to amorphous polymers or low-crystallinity resins such as PLA, ABS, and polyamides. Applying high-crystallinity and fast-crystallizing POM to MEX 3D printing has been extremely challenging due to shrinkage, warping, and poor adhesion to the build platform, preventing its practical use.

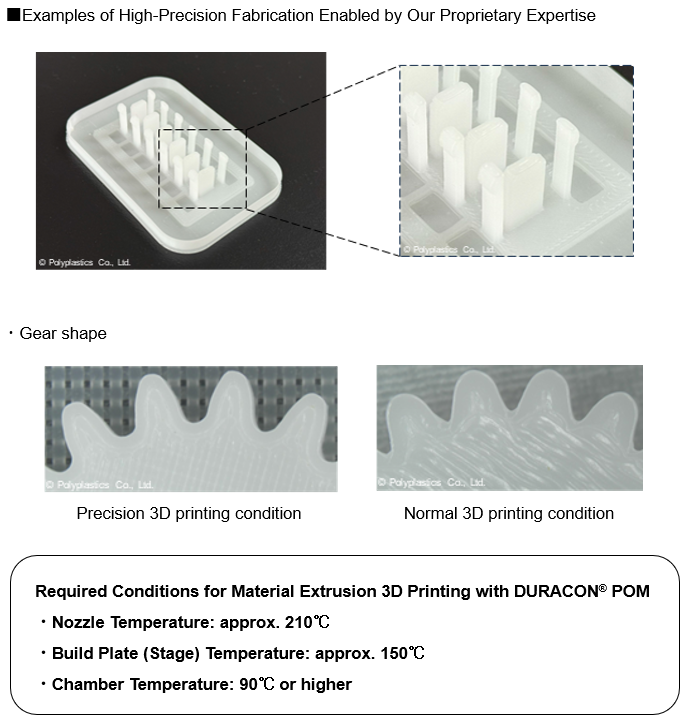

We have established MEX-based 3D printing technology for DURACON® POM by combining a material optimized for 3D printing with proprietary printing conditions.

This technology enables 3D printed parts to achieve physical properties comparable to injection molded products.

Moreover, thanks to our accumulated expertise, high-precision fabrication is possible.

※For details on 3D printers verified for use with this DURACON® POM extrusion-based technology, please reach out to our team.

Support for Technology Implementation

For customers considering the adoption of 3D printing technology using DURACON® POM, we offer technical support for implementation, as well as introductions to contract manufacturing partners equipped to handle POM-based 3D printing.

Feel free to contact us for sample fabrication and support services.

Offering DURACON® POM 3D Printing Technology as a New Solution

We aim to provide DURACON® POM 3D printing technology as a new solution for advanced manufacturing.

We are currently accepting inquiries regarding sample prototyping and introductions to contract 3D printing service providers.

If you have any questions or requests, please feel free to contact our sales representatives or reach out via the website.

Additionally, we offer DURACON® POM AM17X filament prototype (available for purchase).

For more information, please don’t hesitate to contact us.

【Related information】

◆ 3D Printing with POM is now possible

【For inquiries about our technologies and materials, please contact us via 】

◆ Polyplastics Group Representative

◆ WEB Inquiry