Toward a Society

Free from Traffic Accidents

We interviewed DENSO Corporation which uses Polyplastics resins.

Kouji Suda (center), Shinji Kitano (right), AD&ADAS Engineering Div. 2, DENSO Corporation

Daisuke Usui (left), Unit 1, Japan Business Unit, Polyplastics Co., Ltd.

FY20182

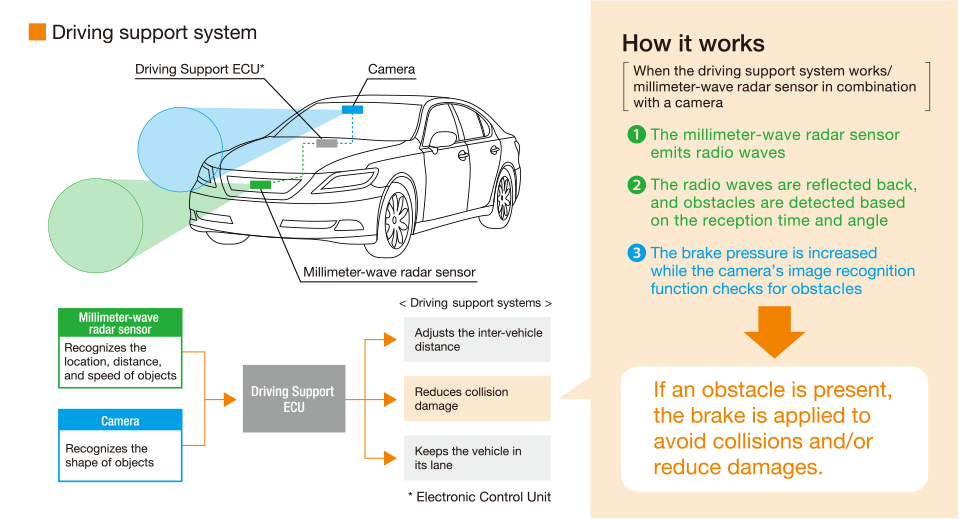

In recent years, vehicles are required to have not only fuel efficiency and environmental performance, but also safety performance, which is necessary to achieve a safer, more secure society free from traffic accidents. Vehicles with such safety performance need the functions to avoid the collisions and/or reduce the damages by detecting the distance between the vehicle and any potential obstacles. One of the technologies that supports such functions is DENSO Corporation’s millimeter-wave radar sensor which uses Polyplastics’ DURAFIDE® PPS.

Functions of Millimeter-Wave Radar Sensor and Performance Required of Resins

Millimeter-wave radar sensor emits radio waves from the front side of the product, and these waves reflect off pedestrians and vehicles ahead and bounce back. Based on the time this takes, the device detects the distance between a vehicle and any objects. This radar is used in collision damage reduction systems (which detect unavoidable collisions and slow the vehicle to reduce collision damage) and inter-vehicle distance control systems (which maintain a certain amount of distance with the vehicle ahead) that can be installed in vehicles.

Millimeter-wave radar sensor devices are generally installed behind the emblem on the vehicle anterior, and therefore are exposed to sunlight as well as heat from the engine compartment. For this reason, the antenna, the heart of the radar is installed inside the housing parts to be protected.

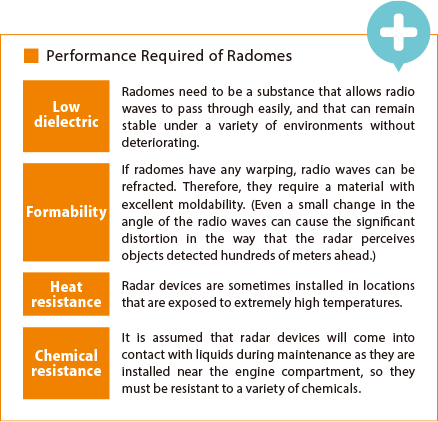

Polyplastics’ PPS resins are used in the radome which is one of the housing parts and located directly ahead of the radar. Radome materials need high strength to protect the electric parts inside, but also must allow the radio waves transmitted by the antenna to pass through. There is a wide variety of other performance demands that cannot be achieved with metal, so we selected PPS which has a good balance of these characteristics.

Technical/Development Support

For these reasons, radome for millimeter-wave radar sensor is required to have a wide variety of performance, so it was necessary to gather individual physical property data during product design. Because Polyplastics already had basic physical property data, there was no need to spend time gathering them and we were able to speed up development. For dielectricity data which was especially important, Polyplastics showed great adaptability; they handled our request promptly before obtaining detailed experimental data at an external organization. Specifically, Polyplastics used its own facilities to confirm beforehand whether DURAFIDE® PPS would meet our expectations for characteristics. We think that this kind of consideration made design development go very smoothly.

Polyplastics even gathered weather resistance data in order to confirm that the laser-printed part of the radome would not deteriorate when exposed to sunlight, rain, or wind. With its highly technological capability, Polyplastics also met our specialized demands. These made it possible for us to commercialize a millimeter-wave radar sensor.

Future Issues and Outlook

In order to achieve a safer, more secure society, we believe that it is necessary to develop sensors that can be installed on any vehicle. This means they need to be compact, lightweight and for a low price.

Unfortunately, because there is not yet a material that can meet these conditions, metal is used for unit parts other than the radome. But there are growing needs to make this part out of resin too.

Future Expectations for Polyplastics

We have high expectations for Polyplastics to continue to develop and provide resins that can achieve miniaturization and weight reduction. We also hope that Polyplastics will keep providing us with prompt information. Also, while there is already a great emphasis on robustness, it is poised to become even more important in vehicle design in the future. Robustness means the mechanism or property of resisting the effects of external factors. Since vehicles are used in a variety of environments and over the long term, it is important that they are robust in order to prevent external changes from causing performance deterioration or malfunctions. And for PPS, we used experiments and data to confirm that, for example, its performance would remain stable even if the resin took in moisture from the air, and that the shape and strength would not change even under the environment of the engine compartment area. This made it clear that we were using a resin that was truly highly robust. We have high expectations for the robust functional resins that Polyplastics will develop in the future.